Understanding Manufacturing Costs

In today’s fast-paced industrial world, the components that drive manufacturing costs are more complex than ever. Factors such as resource availability, technological advancements, labor costs, and global supply chains are all crucial determinants of financial health in the manufacturing sector. Understanding these elements is critical for business leaders looking to optimize their operations and maintain competitive advantages. This exploration into the nuances of manufacturing costs provides actionable insights that can be applied to various industries.

Basic Components of Manufacturing Costs

Manufacturing costs generally fall into three main categories:

- Direct Materials: This includes all raw materials used in production. The cost of materials varies significantly based on quality, supplier contracts, and market conditions.

- Direct Labor: Wages paid to workers directly involved in manufacturing are considered direct labor costs. This can fluctuate based on labor efficiency, wage rates, and overtime requirements.

- Overhead Costs: These include indirect costs such as utilities, depreciation, and maintenance. Understanding overhead is crucial because it can significantly impact the overall cost structure.

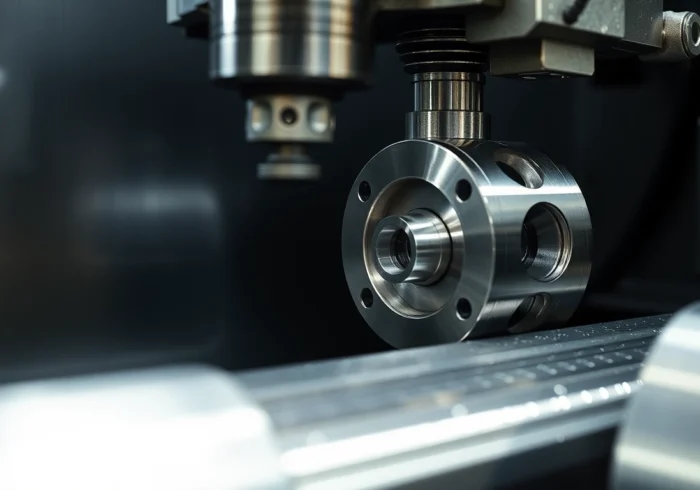

The Role of Raw Materials and Technology

The quality and cost of raw materials play a pivotal role in determining manufacturing expenses. For instance, utilizing sustainable or high-quality materials can result in a competitive edge but may initially increase costs. Technology, particularly advancements in procurement and inventory management, can streamline raw material sourcing and help to control costs effectively. Integration of technologies such as blockchain in supply chain management exemplifies how technology can optimize resource allocation and reduce waste.

Impact of Labor and Automation

Labor costs can significantly differ from country to country, impacting the overall cost of production. Developed countries may face higher wage bills compared to developing nations. However, automation is rapidly changing this landscape. Intelligent automation technologies reduce dependence on labor and enhance productivity by improving manufacturing precision and speed, potentially leading to lower overall costs in the long run.

Key Drivers of Costs

Supply Chain Variability and Its Effects

The supply chain is often the backbone of the manufacturing process. Variability within this chain can lead to unpredictable costs. Disruptions due to natural disasters, geopolitical tensions, or pandemics can hamper production schedules and inflate prices. Consequently, manufacturers need to build resilience in their supply chains through diversified sourcing strategies and robust contingency plans.

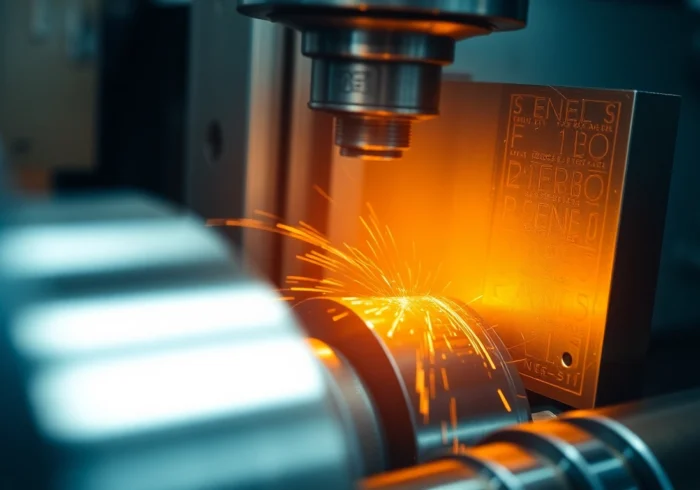

Technological Advancements in Production

Technological innovation in production processes—such as AI and IoT—has transformed manufacturing, leading to increased efficiency and reduced costs. For example, predictive maintenance facilitated by sensors and data analytics allows manufacturers to preemptively address issues before they escalate, minimizing downtime and maintenance costs. Investment in advanced technologies is not merely beneficial but essential for maintaining competitiveness in today’s market.

Global Economic Factors

International economic conditions significantly influence manufacturing costs. Fluctuations in currency exchange rates, trade tariffs, and tariffs on imports and exports impact raw material costs and ultimately affect pricing strategies. Manufacturers must remain agile and informed concerning these economic factors to navigate changes effectively.

Reducing Manufacturing Costs

Leveraging Technology for Efficiency

Manufacturers can reduce costs by adopting technologies that optimize labor productivity and operational efficiency. Implementing enterprise resource planning (ERP) systems helps harmonize operations, streamline workflows, and enhance visibility across processes. Moreover, utilizing data analytics to forecast demand effectively can minimize excess inventory costs and lower waste levels in production.

Best Practices in Inventory Management

Efficient inventory management practices can drastically reduce costs. Just-in-time (JIT) inventory practices, which minimize storage costs by receiving goods only as needed, exemplify this. Additionally, leveraging inventory management software can provide real-time tracking and analysis capabilities, allowing businesses to make educated decisions on replenishments and stock levels.

Investing in Employee Training

Training personnel to adapt to new technologies and processes is pivotal in reducing manufacturing costs. Well-trained employees not only enhance productivity but also improve product quality, reducing rework costs and materials waste. An initial investment in training can yield significant returns through improved performance and lower operational costs.

Case Studies of Cost Management

Successful Tech-Driven Manufacturing Examples

A notable example of effective cost management includes a leading smartphone manufacturer that implemented robotics in its assembly line, drastically reducing labor costs by up to 30% while improving manufacturing speed. This case demonstrates how technology can catalyze efficiency, ultimately leading to a stronger market position.

Lessons from Industry Leaders

Industry leaders often share similar traits in their approaches to cost management. For instance, a global automotive manufacturer embraced lean manufacturing principles, focusing on eliminating waste throughout the production process. This not only reduced costs but also enhanced the overall quality of their output, allowing them to thrive amid stiff competition.

Innovative Solutions That Reduced Costs

Some manufacturers have pursued innovative solutions, such as utilizing additive manufacturing (3D printing) to produce components on-demand, significantly lowering material and storage costs while increasing flexibility in production capabilities. This dynamic approach has enabled them to pivot quickly in response to market demand.

Evaluating Manufacturing Cost Strategies

Metrics for Assessing Cost Efficiency

To effectively evaluate manufacturing cost strategies, businesses should monitor specific metrics such as cost per unit, gross margin, and return on investment (ROI). These indicators provide invaluable insights into where efficiencies can be gained, helping to define the financial health and competitiveness of operations.

Technology’s Role in Cost Evaluation

Modern technologies aid in the evaluation of manufacturing costs by providing accurate and timely data analytics. Integrating advanced software solutions allows for real-time analysis of production costs, providing manufacturers with the insights needed to make informed strategies towards cost reduction.

Future Trends in Manufacturing Costs

As technologies evolve, so too will manufacturing cost dynamics. Trends such as increased reliance on artificial intelligence, machine learning, and automation are anticipated to drive costs down while improving quality control standards. Staying ahead of these trends will be crucial for manufacturers seeking long-term sustainability and profitability.